Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

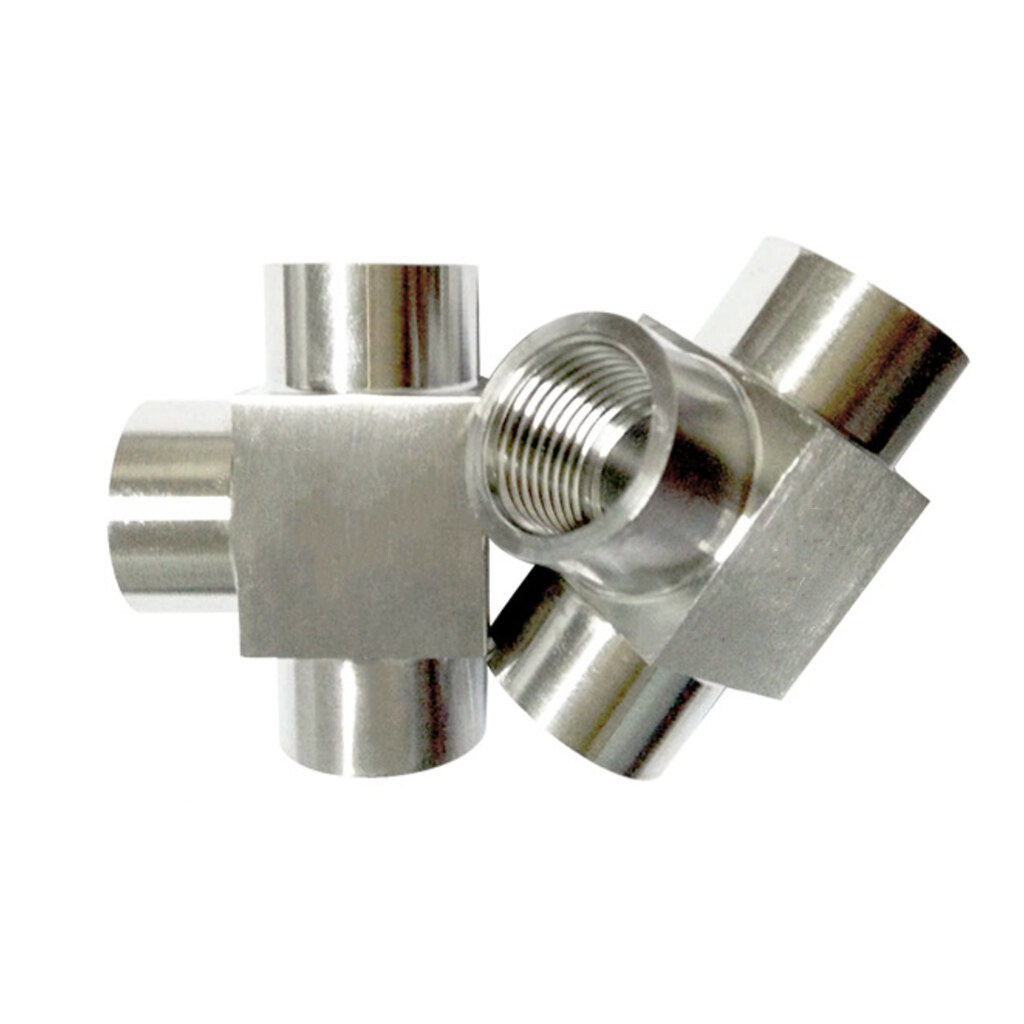

Pneumatic stainless steel joint hose male thread pneumatic pipe elbow connecting pipe

Male Thread for Pneumatic Stainless Steel Joint Hose All parts, with the exception of the sealing ring, are made of SUS316 stainless steel, which has a high level of corrosion resistance. Pneumatic Pipe Elbow Connecting Pipe is simple and quick to install, and it can be disassembled and recycled.

Pneumatic Stainless Steel Joint Hose Male Thread Pneumatic Pipe Elbow Connecting Pipe

Pneumatic Stainless Steel Joint Hose Male Thread Pneumatic Pipe Elbow Connecting Pipe is easy and quick to install, and can be disassembled and recycled; all parts except the sealing ring are made of SUS316 stainless steel, which has strong corrosion resistance.

The installation method of Pneumatic Stainless Steel Joint Hose Male Thread Pneumatic Pipe Elbow Connecting Pipe

1. Remove the burrs after the trachea is cut off, insert one end of the trachea into the joint socket (must be inserted to the bottom), and a firm connection and seal can be achieved.

2. When disassembling the trachea, press the connector ferrule in with your thumb, and pull out the trachea with light force

3. After repeatedly pulling out the trachea. The end wear should be cut off. Continue to use after smoothing.

4. Terminal pipe joints such as right-angle, tee, and cross. After installation, only need to rotate the joint body to adjust the connection direction of the joint

The precautions of Pneumatic Stainless Steel Joint Hose Male Thread Pneumatic Pipe Elbow Connecting Pipe

1. Make sure that the cut surface of the pipe is vertical, there is no scratch on the outer periphery of the pipe and the pipe is not oval.

2. When inserting the tube, be sure to insert it to the bottom of the joint (the tube is inserted about 15MM). If the tube is not inserted to the end, it may cause air leakage.

3. After the pipe is installed, pull the pipe to confirm that the pipe cannot be pulled out. Notes when disassembling the joint:

4. Use a suitable tool to disassemble the pipe joint with the outer hexagon part of the pipe joint

5. Remove the sealing material adhered to the opposite side of the pipe joint. Otherwise, the adhering sealing material may enter surrounding components and cause failure.